Ideally you have been advised to implement a preventative maintenance programme to ensure your UPS is ready to perform when called upon.

Like everything, UPS and battery systems have an expected operational lifetime and will eventually require retirement and replacement.

The service life that you can expect to achieve from your UPS and battery system is impacted by several factors including:

UPS design and manufacture quality

UPS configuration, especially battery discharge and recharge cycles

Physical environment particularly temperature, humidity and air quality

Electrical environment including harmonics

Proactive replacement of consumables such as batteries, filters, fans and capacitors

Whether you have a single UPS system of a distributed fleet of UPS and battery systems supporting your critical business operations, Life Cycle Management is something that should be on your radar.

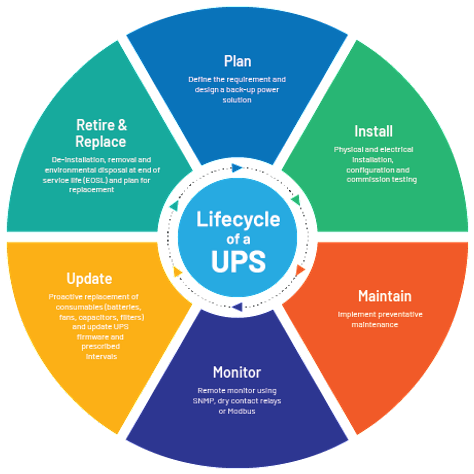

Plan - Define the requirement and design a power quality solution

Install - Physical and electrical installation, configuration and commission testing

Maintain - Implement preventative maintenance

Monitor - Remote monitor using SNMP, dry contact relays or Modbus

Update - Proactive replacement of consumables (batteries, fans, capacitors & filters) and update UPS firmware at prescribed intervals

Retire & Replace - De-commission, removal and environmental disposal at end of service life (EOSL) and plan for replacement

How do you treat your UPS?

We encounter three typical approaches for UPS management and maintenance – which do you use?

Reactive

Run the device until it breaks with little (or no) regular maintenance. Replace UPS on failure. Large potential risk in the event of failure with potential for extended outages whilst a replacement UPS is procured.

Proactive

Standard maintenance performed at predetermined (often yearly) intervals. Some consumables replaced but no true operational visibility. Replace UPS on failure.

Predictive

Ongoing evaluation of maintenance and operational readiness. Monitored evaluation of device performance-health based on testing and life cycle. Replacement is actively planned and budgeted for.

The approach that you take during the service life of your UPS equipment will depend on the criticality of the business operation protected by your UPS solutions and your budget.

Whatever approach you take, you can still be proactive in planning and budgeting for UPS retirement and replacement.

In its simplest form this can be achieved by retaining a record of each UPS and battery system in your fleet, its purchase date and expected service life (from manufacturers documentation)

With this information you can broadly predict when your equipment will be due for retirement and replacement.

All of this information should be available on UPS service reports.

Its never too late to change

Whatever the strategy you follow during the service life of your UPS and battery systems, life-cycle management will provide you with the visibility to ensure operational readiness and pro-actively budget for replacement at end of life.

UPS lifecycle management can deliver affordable and reliable network availability that supports users and the business—reducing risk while satisfying stakeholder demand for continuity.

Partnering with a UPS service provider can provide expertise to configure, deploy, manage, and dispose of UPS devices for optimum Return on Investment and reduced Total Cost of Ownership.

You can also reduce management burdens on IT and facilities management staff by partnering with a dedicated UPS and power quality service provider. They can streamline the UPS management approach by offering equipment, management, and engineering services from a single source to align UPS investments with continuity goals.

Case study one

A retail business has a small 650VA UPS unit deployed on each point-of-sale terminal across their 20 stores. The UPS units are of varying ages and condition. The service life approach adopted is replace on fail.

The lifecycle replacement strategy would be to record the location and anticipated retirement age of each UPS (typically 3-5 years from install), overlaying with the current replacement cost would provide a good indication for budgeting purposes of the replacement costs likely in the coming years.

Case study two

An organisation has a four-rack server room with each rack being supported by a 3kva rack-mount UPS. The UPS equipment is monitored via SNMP providing real time data on UPS status and battery backup time. Each UPS is serviced annually.

The life cycle replacement strategy would be to record the install date of each UPS unit, budget and schedule mid-life battery replacements at 4 years and budget and schedule for total replacement at 8 – 10 years (8 years if the operating environment is poor and 10 years if the operating environment is clean, cool and electrically stable).